泉州(zhōu)聯進機械有(yǒu)限公司

QUANZHOU LIANJIN MACHINE CO., LTD

切

條(tiao)

機

用

Rubber Strip Cutting Machine Usage

用途:用于橡(xiang)膠切條、切紙(zhi)等

特點: 1.裝有(you)防護裝置在(zai)使用時安全(quan)快捷。

2.翻滾切(qie)割,三個刀片(piàn)設計,切料速(su)度快,效率高(gāo)。

3.送料速度可(ke)調,裁斷寬度(du)可調。

主要技(jì)術參數 Technical Parameters | |

型号(hao) Model | LJ-CA08 |

機型 | |

外型尺寸Appearance Size: L*W*H(mm) | 1200*1000*1200 |

工(gōng)作寬度Working Width(mm) | |

功率(lü)Power (KW) | 2.25 |

重量Weight(kg) |

1. 操作(zuo)時不要雙層(céng)料同時切,以(yǐ)免燒壞電機(jī),發現送料滾(gun)筒卷料時,要(yào)及時關機清(qing)理,同時如有(yǒu)雜料在刀口(kou)工作部位要(yao)及時清理幹(gàn)淨,清理時務(wu)必斷開電源(yuan)來源。

2. 原(yuán)料不能有鐵(tiě),石頭等雜物(wu),如發現要清(qing)理幹淨,以免(mian)損傷刀片。

3. 發現電機(ji)有異聲,要停(tíng)機檢查,鏈條(tiáo)皮帶松動要(yao)及時調整,螺(luo)絲松動要及(ji)時緊固。

機台工作時(shí),手一定不要(yao)伸進裏面,如(rú)有問題,一定(dìng)要停機解決(jue)。

6. 如時(shi)間長,發現料(liào)切不斷①調整(zhěng)刀口間隙②修(xiu)整刀口,檢查(chá)刀口是否有(yǒu)損壞,如有損(sun)壞要及時修(xiū)整。

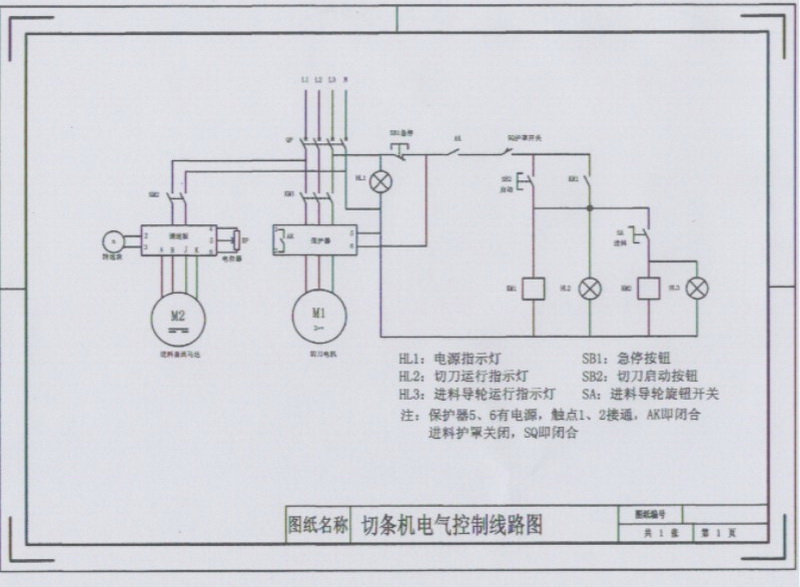

送料(liào)滾筒如卡料(liao),不能啓動①檢(jiǎn)查電控箱内(nei)保險絲是否(fou)燒壞,如燒壞(huai),更換時必需(xu)按原來型号(hào)更換,不要随(sui)意加大規格(ge)。②檢查調整旋(xuan)轉失靈,如有(yǒu)不靈及時更(gèng)換。

兩端(duān)彈簧調整不(bu)能壓得太緊(jin),以免滾卷料(liào),新機台用少(shao)量粉撒在卷(juan)筒上,以免卷(juàn)料。

Size: L*W*H (mm) 1200*1000*1200

Purpose: This machine is used for cutting the rubber, paper etc.

Advantage: 1.Equiped with safety cover to secure safety on working.

2. Revolving blade cuts rubber in high speed and efficiency, with three blade edges.

主要技術(shù)參數 Technical Parameters | |

型号 Model | LJ-CA08 |

機(jī)型Systems | |

外(wai)型尺寸Appearance Size: L*W*H(mm) | 1200*1000*1200 |

工作(zuò)寬度Working Width(mm) | 600 |

2.25 | |

重(zhong)量Weight(kg) | 350 |

INSTRUCTIONS:

1. When operating, do not cut rubber in double-deck at one time, which will cause the MOTOR to be too hot and broken. If the Material-sending Roller can not run smoothly. Please shutdown at once; meanwhile, if there are odds and ends at knife edge, please clean up in time .Do stop the power before cleaning.

2. No iron or stone in the material; if any, take them, away at once, so as not to make the blade damaged.

3. Any unusual voice, stop and check. Adjust chains and screws if they are loose.

5. Add oil to cycloidal needle wheel on time (usually once per three months).

7. In case the material sending roller can not send the material smoothly, you should firstly check and adjust rotary switch; if it can not work effectively, replace a new one in time.